In this keynote presentation, Marc Soucy, PhD, President and co-founder of InnovMetric, explains how you can eliminate significant time losses and process inconsistencies with digital thread technologies. These technologies establish a single source of truth for dimensional inspection data and automate your data flows to deliver 3D measurement data digitally enterprisewide.

Discover how to optimize the efficiency and flexibility of your part measurement process with PolyWorks|InspectorTM 2025. This 20-minute video showcases new functionalities like auto-alignment for faster scanning, automatic large-part inspection, enhanced GD&T calculations, and assisted CMM sequencing for complex CAD surfaces.

Discover how the latest version of the PolyWorks|Inspector™ Gauge R&R workflow lets you certify and improve your 3D measurement process performed through its universal metrology platform.

Learn how to integrate a CAD model revision with PMI within a piece measurement template in PolyWorks|Inspector™ in minutes instead of hours, using our PolyWorks|PMI+Loop™ MBD solution for CAD software.

See how operators can measure large parts more efficiently by scanning with near-me guidance, reviewing inspection results directly on the part, and collaborating with colleagues anywhere via MS Teams using the Microsoft HoloLens smart glasses and PolyWorks|AR™ 2023.

Discover how the inspection project data lifecycles delivered by the PolyWorks Digital Ecosystem accelerate the engineering phase of a new product, automate the propagation of CAD design changes, and help build strong long-term know-how and expertise within a manufacturing organization.

Learn how PolyWorks|AR™, a PolyWorks|Inspector™ mixed reality plug-in for the Microsoft HoloLens smart glasses, radically transforms the experience of measurement operators by superimposing vivid holograms on physical pieces and assemblies.

To obtain trustworthy results, a measurement system analysis (MSA) is performed prior to production through repeatability and Gauge R&R studies. InnovMetric proposes an easy-to-use and fully integrated software solution to perform these studies.

See how we made the transformation and understand how the PolyWorks enterprise solution can directly contribute to enhancing your company’s competitivity and increasing the value of your expertise.

Managing 3D measurement data is a major challenge. The growing popularity of 3D scanning technologies yields large inspection projects. Discover how you can achieve substantial daily productivity gains by using PolyWorks|DataLoop™.

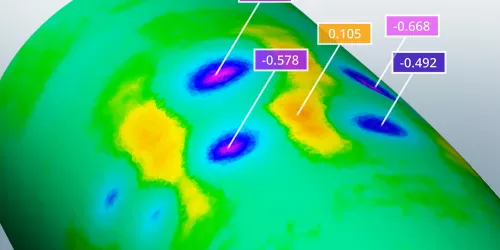

With this new technology, scan your parts and quickly display surface imperfections. Detect bumps, dents, and scratches, monitor part degradation over time, and locate missing functional elements, such as spot welds or rivets.

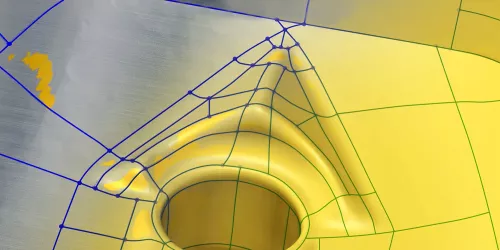

Discover a new groundbreaking automatic surfacing algorithm perfectly integrated within an intuitive curve-based surfacing workflow.

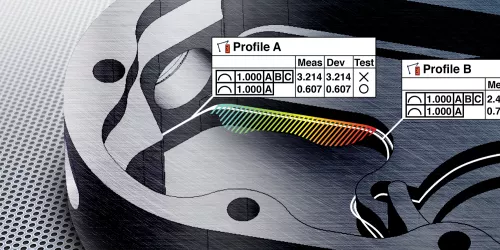

Learn how to efficiently measure and control sheet metal freeform cutouts and part sections by using the enhanced polyline creation and extraction tools along with the new GD&T-compliant line profile tool.

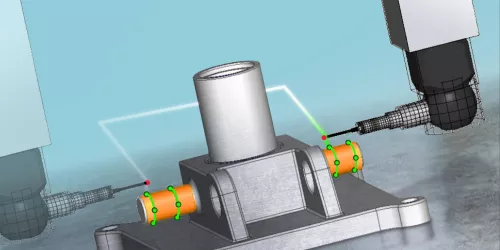

Discover how probing an object using multiple steps can greatly increase the flexibility and power of your measurement sequences with faster run times.

Learn the benefits of integrating PolyWorks® into your production environments.

Discover three preproduction tasks that greatly benefit from our latest innovations.

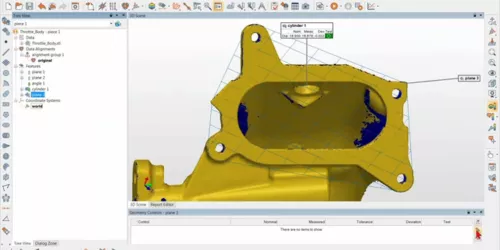

When a part is inspected with the help of its CAD model, the CAD model is used throughout the project to align the part, extract features, and produce pass/fail results. When inspecting a part by scanning without using a CAD model, you go through those same steps obtaining measured-to-nominal deviations but using a different toolset.

With the introduction of PolyWorks|ReportLoop™, a free Excel-based smart reporting solution, you can link spreadsheet cells directly to PolyWorks® inspection project data.